Integrated Tail Spend Management Services

About Tail Spend Management

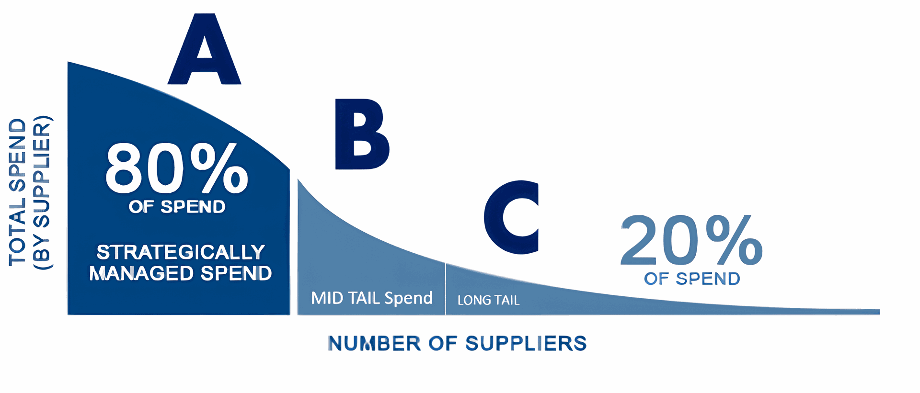

Tail spend refers to small but numerous and dispersed procurement projects within a company. These procurement projects are usually fragmented and low in value, and may have other names such as edge procurement, low-value procurement, sporadic procurement, tail-end procurement, tail spend procurement, and some companies may categorize them as C-class materials.

Whether in terms of procurement amount or types of parts, typically 80% of the procurement amount in a company accounts for only 20% of the total product categories, and also only 20% of the total number of suppliers. The remaining 20% of the procurement amount covers 80% of the product categories and is provided by 80% of the suppliers. However, based on the Pareto 80/20 management principle, this portion of procurement is often overlooked in management.

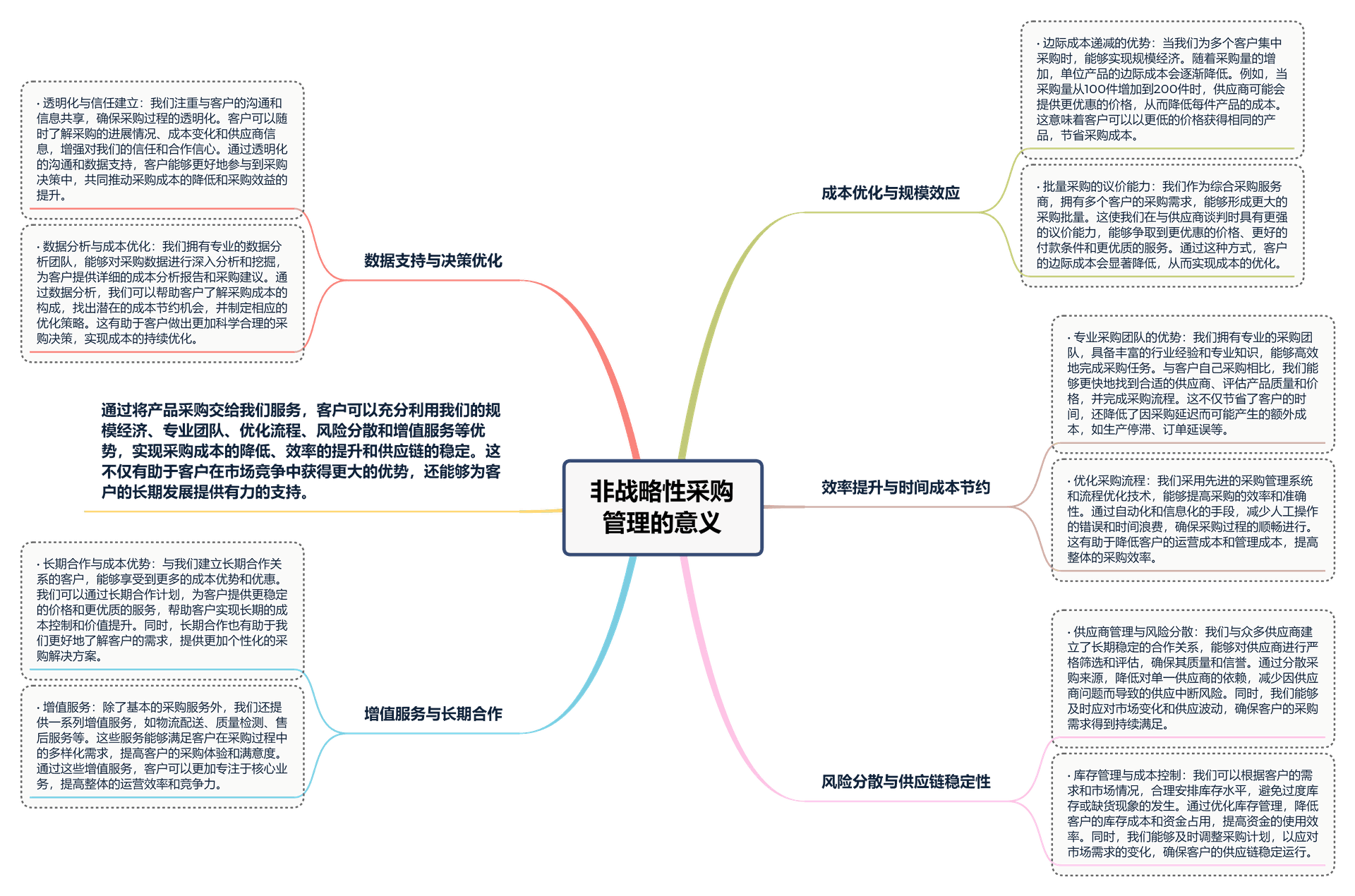

The Significance and Advantages of Tail Spend Management

In an increasingly competitive market environment where labor and time costs continue to rise, enterprises must explore various approaches to reduce costs - including workforce optimization and efficiency improvements - while maintaining focus on core competencies to sustain competitiveness. Consequently, businesses should place greater emphasis on the competitive advantages that effective non-strategic procurement management can deliver. These potential advantages include:

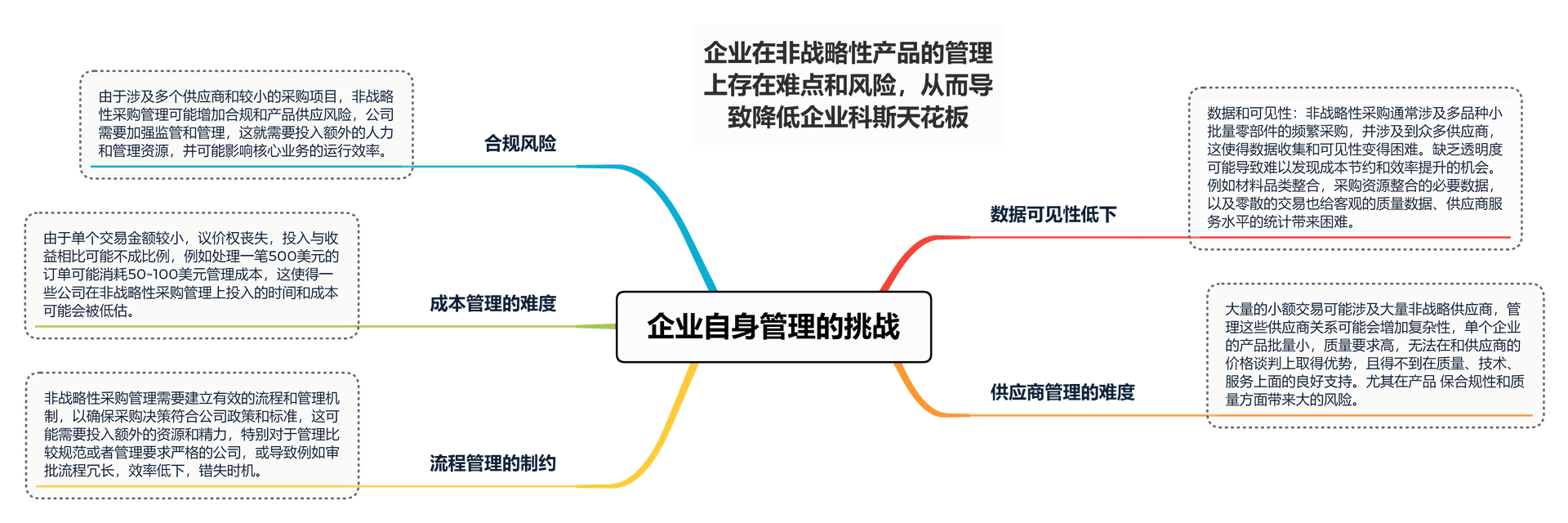

Challages

While Tail Spend management is important, enterprises face several challenges and risks in its execution that may lower the Coasean ceiling of the firm:

Solutions and Services

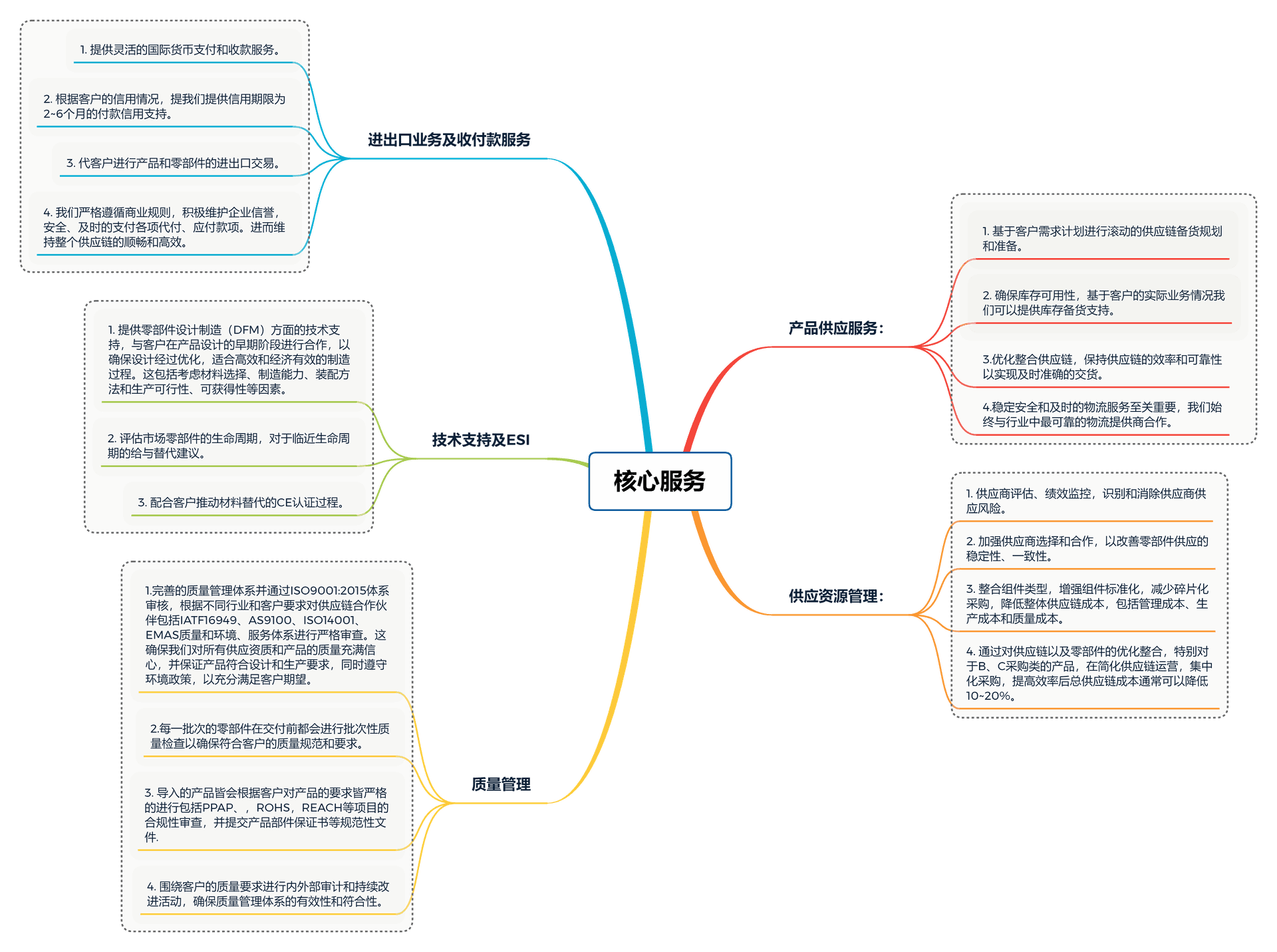

As a professional manufacturing supply chain integration and supply service enterprise, we have been seeking cooperation with potential customers to help them solve the difficulties of tail spend and bring considerable value-added benefits to customers in this area. We are based on the decades of supply chain work experience of the founding team and a professional management team, and have established deep cooperation with many industrial product manufacturing ecological chain companies. With outstanding upstream and downstream supply chain integration capabilities, we provide customers with integrated supply chain and one-stop product component supply services. Our services cover all aspects of supply chain integration, including assembly and supply services of components. By deeply participating in the internal and external supply chain integration process of customers, we help them achieve efficient operation in complex supply chain environments, optimizing supply and quality management costs. We particularly focus on the management of tail spend management projects of multi-product, multi-variety, complex, low-value Class C product categories. Currently, we have thousands of supply resources in various industries and manage and supply thousands of components for customers. We have made positive contributions to customers in supply chain integration, cost, and quality management.

Through the following services, we help clients address pain points in tail spend management, reduce costs, improve efficiency, and enable them to focus on their more critical core business areas: